In today’s rapidly evolving technological landscape, smart manufacturing has emerged as a game-changer in the industry. It refers to the integration of advanced technologies and data analytics into traditional manufacturing processes, resulting in improved efficiency, productivity, and cost-effectiveness.

Click to find more about what is smart manufacturing.

The Essence of Smart Manufacturing

Smart manufacturing encompasses various cutting-edge technologies such as artificial intelligence (AI), Internet of Things (IoT), robotics, big data analytics, and automation. These technologies work together to create a connected ecosystem that enables real-time monitoring, predictive maintenance, optimized production planning, and enhanced supply chain management.

This transformative approach allows manufacturers to make informed decisions based on accurate data insights while streamlining operations for maximum output. By leveraging intelligent machines and interconnected systems throughout the entire value chain, companies can achieve higher levels of agility and responsiveness to market demands.

JVTECH: Pioneering Smart Manufacturing Solutions

One notable player in the field of smart manufacturing is JVTECH – an innovative company dedicated to revolutionizing traditional production methods through technology integration. With their expertise in AI-driven automation solutions and IoT-enabled machinery, they have successfully helped numerous businesses enhance their operational capabilities.

By implementing JVTECH’s smart manufacturing solutions, companies can optimize resource allocation by minimizing downtime through predictive maintenance algorithms. Their advanced robotics systems enable seamless collaboration between humans and machines on factory floors while ensuring precision and safety.

Overmolding vs Two Shot Molding: Choosing Wisely

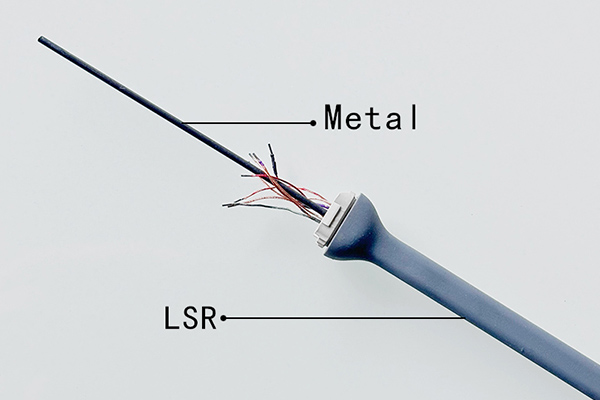

In the realm of injection molding techniques used in smart manufacturing processes like overmolding or two shot molding are gaining significant attention due to their ability to produce complex parts with multiple materials or colors seamlessly integrated into one component.

Overmolding involves injecting a second material onto a pre-molded substrate, creating a strong bond and enhancing product durability. On the other hand, two shot molding utilizes two different materials injected in separate cycles to form a single component with distinct properties.

While overmolding offers cost-effective solutions for adding soft-touch features or improving grip, two shot molding provides greater design flexibility and eliminates the need for secondary assembly processes. The choice between these techniques depends on specific project requirements and desired outcomes.

In Conclusion

Smart manufacturing is revolutionizing traditional production methods by integrating advanced technologies into every aspect of the manufacturing process. Companies like JVTECH are at the forefront of this transformation, offering innovative solutions that enhance efficiency, productivity, and overall operational capabilities.

Whether it’s through leveraging AI-driven automation or utilizing injection molding techniques like overmolding or two shot molding, smart manufacturing enables businesses to stay competitive in an increasingly digitalized world. Embracing these advancements will undoubtedly pave the way for future success in the industry.

Click overmolding vs two shot molding.